how to find Grading of fine aggregate

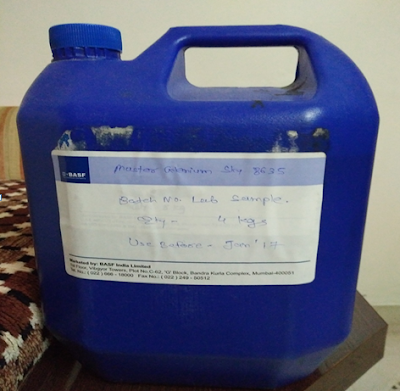

Grading of fine aggregate Apparatus and materials 1. I.S. sieve of size 4.75mm, 2.36mm, 1.18mm, 600μ, 300μ and 150μ . 2. Coarse aggregate 3. Vibrator The sizes between 4.75 mm to 150 micron are termed as fine aggregate. The river sand and crushed sand is used as fine aggregate conforming to the requirements of IS: 383. The river sand is washed and screened to eliminate deleterious materials and over size particles. Procedure 1. 1 kg of coarse aggregates, arranged the set of IS sieves in order with the sieve size increasing to the top, and with pan at the bottom. 2. Before the sieves analysis was performed the Aggregate sample has to be air dried in order to avoid lumps of fine particles and...