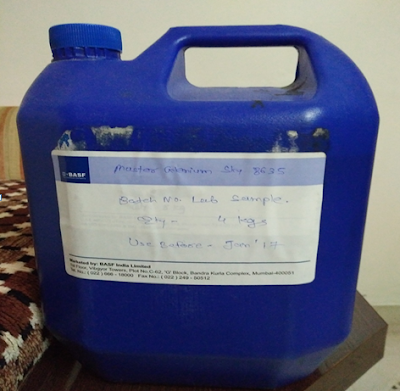

Super plasticizer (SP) & VMA (viscosity modifying agent)

Super plasticizer (SP)

High-range water reducer, also

known as super plasticizer, has made a breakthrough in concrete industry. It is

an essential material component that must be used to produce SCC. The HRWRs

improve the flowing ability of SCC by their liquefying and dispersing actions.

They reduce the yield stress and plastic viscosity of concrete by their liquefying

action and thus provide a good flowing ability in SCC. In addition, the HRWRs

deflocculated the cement particles and free the trapped water by their

dispersing action, and hence enhance the flowing ability of SCC. In dispersing

action, the inter-particle friction and thus the flow resistance are also

decreased, and therefore the flowing ability of concrete is improved.

High-range

water reducers can either increase the strength by lowering the quantity of

mixing water for a given flowing ability, or reduce both cement and water

contents to achieve a given strength and flowing ability. They contribute to

achieve denser packing and lower porosity in concrete by increasing the flowing

ability and improving the hydration through greater dispersion of the cement

particles, and thus assist in producing high strength and good durability

VMA (viscosity modifying agent)

Viscosity-modifying admixture

is relatively a new addition to the family of admixtures for cement paste,

mortar and concrete. The common application of VEA is to produce

non-dispersible underwater concrete and SCC. VMA improves the viscosity and

cohesion of fresh concrete, and thus reduces the bleeding, surface settlement

and aggregate sedimentation resulting in a more stable and uniform fresh

concrete. In addition, VMA makes the fresh concrete more robust and less

sensitive to the small variations in the conditions and proportions of other

constituent materials.

Rixom and Mailvaganam (1999)

have categorized the VMAs into five classes based on their physical actions in

concrete. The classification is as follows:

Class A: Water-soluble

synthetic and natural organic polymers, which increase the viscosity of

concrete by increasing the viscosity of mixing water.

Class B:

Organic water-soluble flocculants, which increase the viscosity of concrete by

enhancing interparticle attraction between cement particles

Class C: Emulsions of various

organic materials, which improve the viscosity of concrete by increasing

interparticle attraction and supplying additional superfine particles in the

cement paste.

Class D: Water-swellable

inorganic materials of high surface area that improve the viscosity of concrete

by increasing the water-retaining capacity of the concrete.

Class E: Inorganic materials of

high surface area that improve the viscosity of concrete by increasing the

content of fine particles in concrete, and thereby resulting in greater

viscosity.

Most widely

used VEAs for concrete are of Class A. The VEAs under this class can be further

subdivided into natural, semi-synthetic and synthetic polymers.

Comments

Post a Comment