How to Find specific gravity of coarse aggregate

specific gravity of coarse aggregate

Apparatus

and materials

1.

Spring

balance

2.

Weight

balance

3.

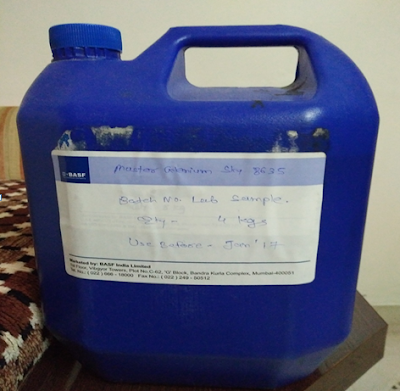

Coarse

aggregate of weight 2kg

4.

Bucket

5.

Water

tank

6.

Oven

Procedure

1.

Aggregate not less than 2 kg was taken. It was carefully washed to eliminate

the finer particles and dust.

2.

It was then positioned in a wire basket and deep in distilled water

at a temperature between 22° to 32°C.

3.

Immediately after absorption, the entrapped air was removed from

the sample by lifting the basket it 25 mm above the base of the tank and

allowing it to drop 25 times at the rate of about one drop per sec. During the

operation, caution was taken that the basket and aggregate remain completely

immersed in water.

4.

They

were kept in water for a period of 24 ± 1/2 hours afterwards.

5.

The basket and aggregate were then jolted and weighed (weight A1)

in water at a temperature 22° to 32° C.

6. The basket and the aggregate

were then removed from water and allowed to drain for a few minutes and then

the aggregate was taken out from the basket and placed on dry cloth and the

surface was gently dried with the cloth. The aggregate was transferred to the

second dry cloth and further dried.

7. The empty basket was again

immersed in water, jolted 25 times and weighed in water (weight A2).

8. The aggregate was exposed to

atmosphere away from direct sunlight for not less than 10 minutes until it

appears completely surface dry. Then the aggregate were weighed in air (weight

B).

9. Then the aggregate were kept

in the oven at a temperature of 100 to 110°C and maintained at this temperature

for 24 ± 1/2 hours. It was then cooled in the air-tight container, and weighed

(weight C).

A= the weight in gm of the

saturated aggregate in water (A1 – A2),

B = the weight in gm of the

saturated surface-dry aggregate in air, and

C = the weight in gm of

oven-dried aggregate in air.

Comments

Post a Comment