SELF COMPACTING CONCRETE

Introduction about self compacting concrete

Self – compacting concrete (SCC) is a fluid mixture, which is suitable

for placing difficult conditions and also in congested reinforcement, without

vibration. In principle, a self – compacting or self – consolidating concrete

must have a fluidity that allows self – compaction without external energy

remain homogeneous in a form during and after the placing process and flow

easily through reinforcement

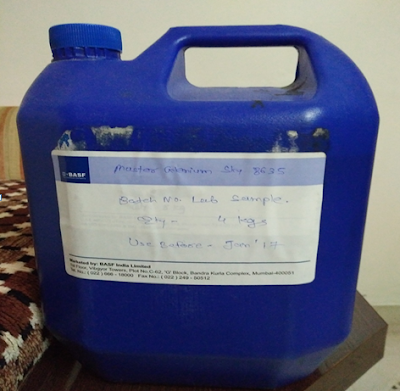

Self-consolidating concrete consists of cement, aggregates, water, and

chemical admixture and/or VMA. Most common chemical admixtures used for SCC are

HRWR, VMA and AEA. Aggregates, cement, water, and HRWR are the principal

materials whereas SP, VMA, AEA, and other chemicals can be used as the optional

materials.

The three properties that characterize a concrete as self-compacting

Concrete are Flowing ability—the ability to completely fill all areas and

corners of the formwork into which it is placed Passing ability—the ability to

pass through congested reinforcement without separation of the constituents or

blocking Resistance to segregation— the ability to retain the coarse components

of the mix in suspension in order to maintain a homogeneous material.

background of self compacting concrete

Self-compacting concrete was first developed 1988 in order to achieve

durable concrete structures. Since then, various investigations have been

carried out and the concrete has been used in practical structures in Japan,

mainly by large construction companies. Investigations for establishing a

rational mix-design method and self-compact ability testing methods have been

carried out to make the concrete the standard one.

For several years beginning in 1983, the problem of the durability of

concrete structures was a major topic of interest in Japan. To make durable

concrete structures, sufficient compaction by skilled workers is required.

However, the gradual reduction in the number of skilled workers in Japan's

construction industry has led to a similar reduction in the quality of

construction work. One solution for the achievement of durable concrete

structures independent of the quality of construction work is the employment of

self-compacting concrete, which can be compacted into every corner of a

formwork, purely by means of its own weight and without the need for vibrating

compaction. The necessity of this type of concrete was proposed by Okamura in

1986. Studies to develop self-compacting concrete, including a fundamental

study on the workability of concrete, have been carried out by Ozawa and

Maekawa at the University of Tokyo.

The prototype of self-compacting concrete was first completed in 1988

using materials already on the market. The prototype performed satisfactorily

with regard to drying and hardening shrinkage, heat of hydration, denseness

after hardening, and other properties. This concrete was named ―High

Performance Concrete.

At almost the same time, ―High Performance Concrete‖ was defined as a

concrete with high durability due to low water-cement ratio by Professor Aitcin

ET. Al. Since then, the term high performance concrete has been used around the

world to refer to high durability concrete. Therefore, Okamura has changed the

term for our proposed concrete to ―Self-compacting concrete.

testing required for S.C.C.

slump flow test

- slump flow test is simplest and most commonly adopted test method for evaluating self compatibility of self compacting concrete.

- This test consists of measurement of the mean diameter in two perpendicular direction of the concrete spread after the concrete had stopped flowing

- slump flow value is between 650 to 800 mm for self compacting concrete.

v-funnel test

- It consists of a funnel with a rectangular cross section

- The concrete is poured into the funnel with a gate blocking the bottom opening

- When the funnel is completely filled, the bottom gate is opened and the time for the concrete to flow out the funnel is noted

- A flow time less than 12 seconds is recommended for a concrete to qualify for a self-compacting concrete

SFRC is a concrete that has a homogenous distribution of randomly oriented discontinuous and discrete steel fibres. So if you want to make your building strong so you should VISIT HERE for tips.

ReplyDelete